Skip to content

WICHARD LIKE YOU HAVE NEVER SEEN IT BEFORE

Founded in 1919, Wichard has never stopped maintaining a strong presence in markets with special safety concerns like aeronautics, automotive, marine, medical, parachute hardware, etc….

Well known around the world for their range of marine products, Wichard remains discreet about their production facilities in Auvergne… However the know-how involved from the design to the assembly stage is incredible – almost a century of expertise tailored to their customer’s needs. Design, tooling, forging, treatments, finishing, machining, quality inspection and assembling…unlike many manufacturers nowadays, all stages are still done under one roof in the center of France.

Experts in precision forging, the French company is able to forge very small parts (from 1g to 1kg) with close tolerances, which serve the medical and aeronautics industries very well. They work with different materials such as steel, stainless steel, aluminium, carbon and titanium.

They have small and medium-size production runs, using power hammers and large-scale production runs as well as using its automatic forging machines (up to 5000 parts/hour).

Wichard is an ISO 2001 , ISO 13485, ISO 14001 and ISO 9100 certified company, also committed to continuous reduction of its environmental footprint through optimization of raw material, energy and recycling.

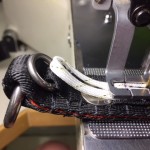

At Wichard Pacific we have also diversified our clientele in Australia & Asia-Pacific over the past 16 years, and we are proud to count a solid database of many different players in sky diving, fire rescue, lifting, helicopter safety, parachutes etc…below are a few applications recently using Wichard parts. The marking stamped on our shackles and snap hooks is the WLL – Working Load Limit – which has been compulsory in Europe and the US for a few years. It has become very useful for those heavy lifting applications requested by some of our customers.