Skip to content

EVERYTHING YOU WANT TO KNOW ABOUT ROPES

We thought Justin Mulkearns from Sydney based company MY YACHT, exclusive Australian dealer for the French rope manufacturer LANCELIN, would be a good person to get an update on the current state of the rope market

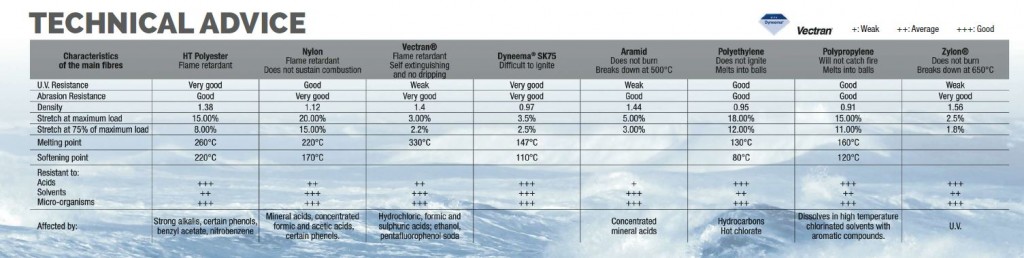

Can you summarize what today’s most trendy fibers are used for in rope, and what the pros and cons of each type are ? There are some fibers in rope manufacturing with some great names that sound very trendy and technical. Dyneema, Zylon, Technora, Vectran, Nomex, and cordura to name a few.

Each fiber has a specific characteristic that the rope manufacturer can use in order to change the outcome of the ropes life or performance. Grip, slip, creep, heat, cost and strength are all considered.

Dyneema has had the most development in recent times and has become the fiber of choice for most manufacturers to use in the core of their ropes. DSM – the company behind the fiber DYNEEMA – has made changes to the UHMWPE fiber to improve modulus, reduce creep and increase abrasion resistance. The SK99 fiber is the latest iteration of this fiber, which is great for standing rigging like back stays and running rigging where you’re looking for the smallest diameter and high break loads. Dyneema is incredibly strong and has very low creep whilst being light but does have a low melt point.

Zylon is more commonly known as PBO and is used in covers of performance rope either blended or on its own. It has a very high melt point but a very short life span, as it does not like UV light abrasion, and cost is also very high. You might see Zylon used in a runner tail or mainsheet of a maxi race boat.

Technora is a fiber most commonly used in the covers of performance rope if you’re looking for a high melt point and high grip properties. It comes in black and yellow. If you’re looking for extra grip in a clutch a pure Technora cover will solve that.

So when choosing the best ropes for your boat, you need to think about the way in which you use it, are you a cruiser, racer or a little bit of both ? Are you looking for high performance and ultimate weight saving and willing to compromise on longevity ? What deck hardware do you have currently, as this will restrict the sizing options also.

What are the latest innovations in the industry, and where do you see the future of rope heading?

Rope innovation in the past 10 years has seen great advances. So many industries, not just marine, are now replacing wire with fibre, due to the weight saving that can be achieved , as well as the safety factor. Handling fibre is a great benefit as opposed to wire or chain, which makes it a very good option for many applications.

As new fibers on the market have reduced the creep and increased the break strength, the diameters can be reduced to a point where the current deck hardware i.e. clutches and winches are not compatible. It is possible to have a 7mm tack line or spinnaker sheet for a 50-60 footer but you would have trouble finding a reliable clutch solution at full load. Handling such small rope would be an issue for some people too. So, rope producers have had to develop in other areas. For example, the new range of performance line from Lancelin has a small yet high tensile core with an increased jacket to core ratio. Which makes it work with the current and older deck gear while also increasing the lifespan of the line and reducing the cost. Lancelin has development partners such as SODEBO maxi trimaran who help by providing a test platform in real time and provide feedback on new ideas and products. They can put a set of running rigging through a lifetime of sailing in a single offshore race.

The innovations taking place in the high end market are weight saving measures, we are seeing a lot more fibre rigging replacing traditional wire. An area that we are seeing this flow through into the mainstream market is the furling cables, not just for flying sails such as asymmetric spinnakers and code zero’s, but also upwind jibs and genoas.

You recently supplied rope for Lisa Blair’s boat Climate Action Now, can you tell us how you chose the ropes for her boat keeping in mind that she would be entering such extreme weather systems ?

For a project like Lisa Blair and her yacht Climate Action Now many factors had to be considered to give her the most reliable and best performing rope package possible. As Lisa would be sailing in the Southern Ocean, known being some of the coldest and angriest seas on the planet. The weather and huge amounts of miles sailed on one tack can play havoc on certain types of rope, so we had to factor this into her rope package.

Some fibers used in rope can absorb water and once they freeze it can become an issue for safety and handling. So Dyneema, which does not absorb water, was used exclusively for the core of all halyards, sheets, tack lines, reef lines, runners and all control lines. We provided Lisa with Lancelin chafe guard made from pure Dyneema to be put on the tips of all hardware areas to increase the lifespan as chafe is inevitable. All working lines like Jib sheets, main sheet running backstay tails and traveler lines were made with hi-tech blended jackets using Polyester Technora and Dyneema in various ratios.

We spent some time consulting with Lisa and her rigger about what style of deck hardware she planned to use and made the diameter to suit for best performance. As well as longevity as we wanted to ensure there was no issues with performance or chafe during her voyage.

For a project like this it was about making it around safely and reliably more so than about trying new and unproven products for small gains.